iamcam

The perfect automated PCB front-end workflow

A new standard for PCB front-end workflow automation

Ucamco's iamcam automates PCB front-end tasks and integrates business systems. This cuts the error rate and the need for operator intervention. It is, by all standards, an exceptional answer to the daily challenges of front-end and production professionals who need to increase quality, reduce errors and drive cost out of the processes. It enables unparalleled workflow automation with rocksolid quality control.

iamcam is highly scaleabe and serves as the heart of any size front-end production operation. It can be configured for simple two to four layer prototype shops, as well as for the most advanced HDI jobs, sequential build, backdrill, flex-rigid.

More with less

Decimating human error while at the same time boosting throughput, it empowers front-end professionals to deliver increased quality at reduced cost in a shorter time.

Versatility to the core

iamcam fits any size front-end production operation, grinding away run-off-the-mill 2 to 4-layer QTA prototypes, as well as advanced HDI, sequential build, back-drilled or flex-rigid products.

Combining intelligence-aided CAM with web technology

iamcam is an entirely new paradigm in front-end software. At its heart is a sophisticated AI-based server, packed with highly advanced PCB functionality, ranging from automatic input, over automated DfM and automatic lay-out optimization, up to assembly and production panel generation.

And in case the AI engine – we call her Ylise – needs a hand or the judgement of a human, easy-to-use, wizard-like web-based applications are at hand, tailor-made to swiftly address a particular issue and have the job continue in the workflow in no time. “Hiccups” like this can readily be dealt with by less technically skilled staff, freeing up your high-end resources for the more challenging tasks.

And requiring merely a simple web browser to operate, iamcam’s web-apps are easy to access both in-house and off-shore, from wherever you have designed your network to reach.

Seamless integration with 3rd party systems

iamcam comes with extensive business system integration capabilities. It integrates seamlessly with any existing infrastructure (ERP, PPS, website, mail server…). Front-end operators or administration departments can easily interact with the workflow through a transparent user interface. The ERP system can drive the flow of individual jobs, and be driven by it, through iamcam's simple but powerful workflow scripting.

It accepts fabrication data in a wide range of formats, including native CAD formats for Eagle and Altium. It generates data in standards such as PDF, XML and Excel (XLSX).

Compatible with your incumbent CAM system

Ucamco protects your investment in licenses and operator training.

Web-based client/server front-end software

iamcam is an entirely new paradigm in front-end software. The core of iamcam is sophisticated AI based server applications, with advanced PCB functionality, for automatic input, automatic DfM, automatic job correction and optimization of the single PCB, automatic panelization. When the server needs operator assistance for a simple task, such as selecting an outline out of a range of outlines, it provides an easy to use, wizard driven, easy to learn web application dedicated for this specific task. These can typically be handled by other than the highly technically skilled operator. The standard web applications, running in a browser, can be run anywhere globally, to where the network reaches.

Benefits

Avoid most human errors

Build quality into your front-end processes and further enhance it with our comprehensive range of automated DfM checks. Automated DfM enables a comprehensive pre-flight check of the received fabricaton data, with nothing missed, even before an order confirmation goes out.

Increase efficiency & throughput

By standardizing your processes and offloading routine tasks to the automated workflow software, you significantly increase throughput.

Save time & money

Handle 50% more jobs without the need to increase your headcount.

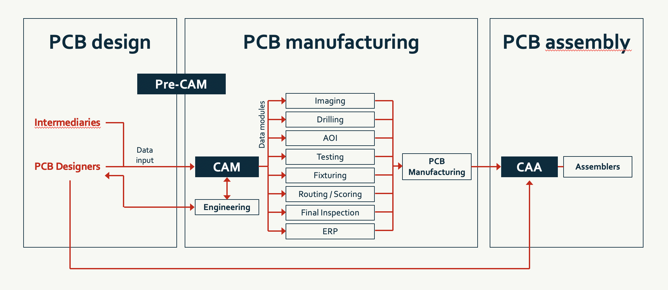

Image: Ucamco software in the value chain

iamcam webinar

For more information about the iamcam concept, please request our iamcam webinar video via presales@ucamco.com

Latest news about iamcam

- 15/12/2021 Apache log4j official statement

- 15/12/2020 PCB007 Magazine lauds iamcam

- 07/09/2020 iamcam webinar: the perfect automated PCB front-end workflow!

- 07/02/2020 Interview with Luc Maesen at IPC APEX expo in San Diego

- 12/12/2019 Interview with Karel Tavernier at Productronica

- 06/11/2019 Adeon-Ucamco Learning Seminar in January